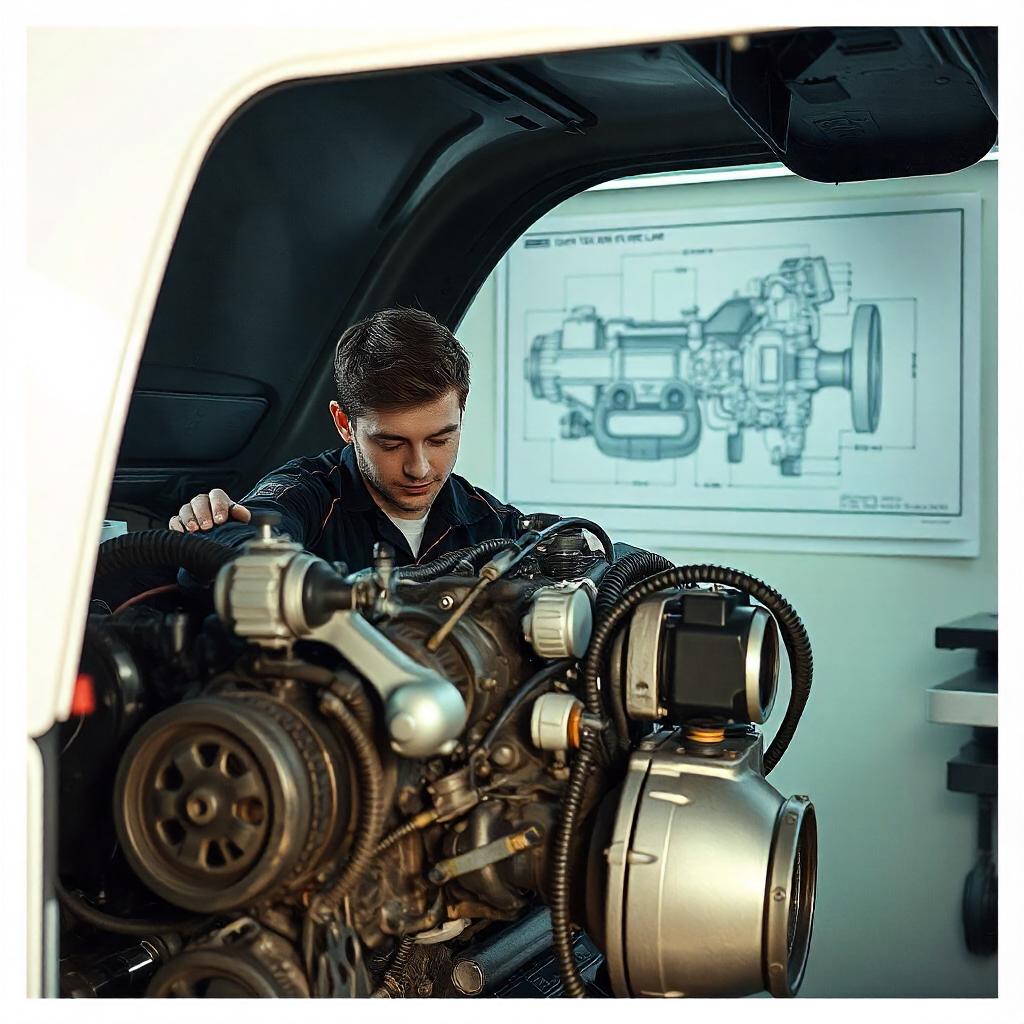

Reducing engine repairs is crucial for maintaining the performance, longevity, and cost-efficiency of vehicles and machinery. One of the most effective ways to prevent engine issues is by using high-quality diesel fuel, engine oil, and spare parts. These components play an essential role in minimizing wear and tear, preventing breakdowns, and ensuring optimal engine operation. Below are key strategies for reducing engine repairs through careful selection and maintenance of diesel fuel, engine oil, and spare parts.

1. Use High-Quality Diesel Fuel

The quality of diesel fuel directly impacts engine performance and durability. Low-quality or contaminated diesel can cause harmful deposits, clog fuel injectors, and damage the engine over time. Contaminants in fuel, such as water and dirt, can increase friction and cause corrosion in the fuel system, leading to engine failure.

To reduce engine repairs, always use high-quality, clean diesel fuel that meets the manufacturer’s specifications. Regularly check and clean the fuel system to avoid any accumulation of harmful substances. Additionally, invest in fuel additives that help clean the fuel system, enhance fuel quality, and reduce the formation of carbon deposits in the engine.

2. Regularly Change Engine Oil

Engine oil serves as the lifeblood of an engine, ensuring smooth operation by reducing friction, cooling engine parts, and cleaning contaminants. However, over time, engine oil degrades and becomes less effective at performing these functions. If oil changes are neglected, the oil may fail to lubricate the engine properly, resulting in excessive wear, overheating, and potential engine failure.

To reduce engine repairs, follow the manufacturer’s recommended oil change intervals and always use high-quality engine oil suited for your vehicle or equipment. Premium oils contain additives that protect against rust, oxidation, and sludge buildup. Regular oil changes prevent the oil from losing its protective properties and help maintain engine efficiency, reducing the risk of costly repairs.

3. Choose the Right Spare Parts

The quality of spare parts used in repairs or replacements can significantly impact the longevity of an engine. Low-quality or incompatible parts can cause poor performance, misalignment, and premature wear. Using high-quality, OEM (Original Equipment Manufacturer) or trusted aftermarket parts ensures that the components fit correctly and function as intended.

Investing in quality spare parts helps maintain optimal engine performance, reduces the likelihood of breakdowns, and improves the overall lifespan of the engine. Regularly check for signs of wear in critical components, such as filters, belts, and hoses, and replace them with high-quality spare parts before they fail. Using the right parts during maintenance and repairs ensures the engine operates smoothly and avoids unnecessary damage caused by subpar components.

4. Maintain Proper Oil Levels

Both overfilling and underfilling engine oil can cause problems for the engine. Overfilled oil can result in excessive pressure, causing seals and gaskets to fail, while low oil levels lead to insufficient lubrication, causing parts to overheat and wear prematurely.

To avoid engine damage, regularly check the oil level and ensure it remains within the recommended range. If the oil level is too low, top it off with the appropriate oil type and viscosity. Ensure you do not overfill the oil, as this can lead to excessive pressure in the engine and other complications.

5. Monitor and Replace Filters Regularly

Filters, including the oil filter, air filter, and fuel filter, are critical for engine health. The oil filter removes contaminants from the oil, while the air filter prevents dirt and debris from entering the engine. The fuel filter ensures that only clean fuel enters the engine’s fuel system. If these filters are clogged or damaged, they can cause poor engine performance and increase wear.

Regularly inspect and replace filters according to the manufacturer’s recommended schedule. By using high-quality filters and replacing them on time, you can ensure that contaminants do not damage the engine and reduce the need for extensive repairs.

6. Keep the Cooling System in Check

The engine cooling system is vital for maintaining optimal engine temperatures. Without proper cooling, the engine can overheat, leading to damage of components such as the cylinder head, pistons, and gaskets. Overheating is one of the leading causes of engine failure and expensive repairs.

To prevent overheating, regularly check the coolant level and inspect the radiator, thermostat, and hoses for signs of wear or leaks. Always use the recommended coolant type and ensure that the cooling system is flushed and maintained periodically. A well-functioning cooling system prevents engine overheating, helping to reduce repairs related to heat-related damage.

7. Use the Correct Fuel Additives

Fuel additives can help protect your engine from the damaging effects of poor-quality fuel. These additives clean fuel injectors, prevent carbon buildup, and improve fuel efficiency. For diesel engines, fuel additives can also improve lubrication and reduce the risk of fuel system damage.

Adding fuel additives to your diesel fuel at regular intervals can improve combustion, reduce engine stress, and help prevent the formation of harmful deposits. It’s essential to choose additives that are compatible with your vehicle or equipment’s specifications to ensure optimal results.

8. Implement Regular Engine Maintenance

In addition to using quality fuel, oil, and spare parts, routine maintenance is critical for reducing the need for engine repairs. Following a regular maintenance schedule allows you to identify and address potential problems early, before they escalate into costly repairs.

Make it a habit to inspect key engine components, such as belts, hoses, and exhaust systems, and replace any parts that show signs of wear or damage. Regular maintenance ensures that the engine operates at its best and helps catch issues before they result in significant repairs.

9. Monitor and Address Engine Performance Issues Early

Any abnormal sounds, vibrations, or changes in engine performance should be addressed immediately to prevent further damage. Unusual behavior, such as poor fuel economy, increased emissions, or knocking sounds, may be an indication of underlying engine problems. Ignoring these issues can lead to serious damage and expensive repairs.

By addressing engine performance issues early, you can prevent further damage and reduce the need for repairs. Regularly monitoring your vehicle’s or machinery’s performance allows you to identify and address small problems before they turn into major failures.

10. Train Operators on Proper Handling

Operators play a crucial role in maintaining engine health. Educating drivers and operators on proper vehicle handling and maintenance procedures can prevent misuse, reduce wear, and ensure that the engine is running efficiently. Encourage safe driving practices, such as avoiding harsh acceleration, overloading, and excessive idling, which can all contribute to engine stress and premature wear.